New initiatives and equipment are all for maintaining quality

Aihara Shuzo is one of the top breweries in the prefecture in terms of the sake making rice used, the average polishing ratio, and the percentage of specially designated sake. Regular sake only makes about 5% of production. In addition, only Yamada Nishiki or Omachi rice is used for the koji (except when displayed as using 100% specially designated sake rice).

He is also very particular about the rice used, and says, “Rice these days doesn’t dissolve easily and releases water easily. That’s why we can’t use the same methods as previously to make good koji.” So he has introduced a floor-type koji making machine by Hakuyoo to control the moisture. Most of the machines use wood on the inside, but he decided to use aluminum to avoid even the slightest smell or taste of wood. In addition, from the “mori” stage, two ginjo-type koji machines (super thin, 5-stage type), also by Hakuyoo, are used in parallel. He purchased the machine three years ago, liking the fact that “the mycelium does not grow outside,” and now he uses the same machine to make daiginjo to sake for entering exhibitions. The brewery has a reputation for using as little machinery as possible and adhering to hand-made sake. So what does this mean?

“It is true that we’ve long adhered to hand-made, however, if the rice is not good, we couldn’t produce good koji even with a tray. Thinking it might not be a one-off that year but likely to continue for all rice in the future, we decided to introduce the machine. Whether it is done by hand or by a machine is of no importance – what is important is to use the best method that enables us to make the sake we desire.

It is not easy to change methods in the “koji making step” which is an important process. Such an investment requires huge capital, and also the understanding of the toji and other brewers. Even so, the strong desire to “make even better sake” led to making the major decision. Since using the machine, the reviews of his sake has in fact improved.

A super-thin, 5-stage type koji making machine is used. Only 4 breweries exist in Japan that use two machines in parallel.

The humidity in the 5-stage koji making machinery is controlled using a dehumidifier.

The sake storage tanks are kept in a refrigerated room.

The brewery that continued to grow despite the ups and downs

“We were founded in 1875…” began Aihara, talking about the history of the brewery. Starting with the sake ranking system in the Meiji era, a temporary shut down during the war time corporate restructuring, and hiccups from rebates sales and introduction of paper packs. Then, in 1979, the company won its first gold medal in the Annual Japan Sake Awards.

“After that, we won gold medals consecutively in 1983 and 1984, yet the sake did not sell,” he said. “However, when we won in 1986, we got a lot of interest and we sold award winning sake even from previous competitions.”

Just when things looked like they were about to take off, their brewmaster was poached. At a time when winning a gold medal was directly related to sales, he missed out on the award for seven years. During this time, however, he continued to trial new brewing methods, thinking, “Even if we don’t win a prize, if we can make the sake as good as those for exhibitions, they will sell”, and “let’s try making nama-zake (unpasteurized sake)”, and “let’s make junmai into tokubetsu junmai”. Then, in 1998, their rival Horimoto Shuzo which produced “Kinsen”, went bankrupt, so he invited Atsushi Horimoto, who was 39 years old at the time, to be the toji at his brewery. Thinking that he would be able to make daiginjo that is rich in aroma, like the Kinsen, he equipped the brewery with a perfect refrigerating system, but it was then that Aihara’s tastes began to change.

“From sake that is fragrant, I found myself liking sake that you can never tire of.”

Then, the shift towards the current “elegant and beautiful food pairing sake” began. Supporting this in the back was the Horimoto’s heightened sensibility and techniques.

Gradually, “Ugo no Tsuki” gained traction, and the company began to receive offers from sake retailers outside the prefecture. The company also achieved overseas expansion. However, when Aihara asked himself, “Who do I really want to cherish?” the answer he reached was “the local people”. As though to prove this, he is actively involved with local restaurants and liquor stores and has built a good relationship with them.

Despite being this enthusiastic about brewing and cherishing the local community, Aihara surprisingly had no intention of taking over the family business. He jokes, “I came back here with the intention of closing the business, so what am I doing still making sake?” He also adds.

“Recently, I’ve been thinking that even though life may have a fork in the road, the end point is all the same.”

When he took on the responsibility at Aihara Shuzo, the term “Daiginjo” did not even exist. It could not be sold in Kure City, and there was a time he was going to Yamaguchi prefecture next door to sell. In contrast, once being awarded the Gold, they sold like hot cakes and were fawned over, experiencing rapid changes. The twists and turns he endured must have been extraordinary.

This might be why. The reason why Aihara holds nothing back from sharing his knowledge and techniques openly, and treasures his relationships with young local brewers and restaurants. His approach of thinking of new ways to make this and that, just might be how he is truly enjoying his life’s calling, a destination he has found himself having arrived at.

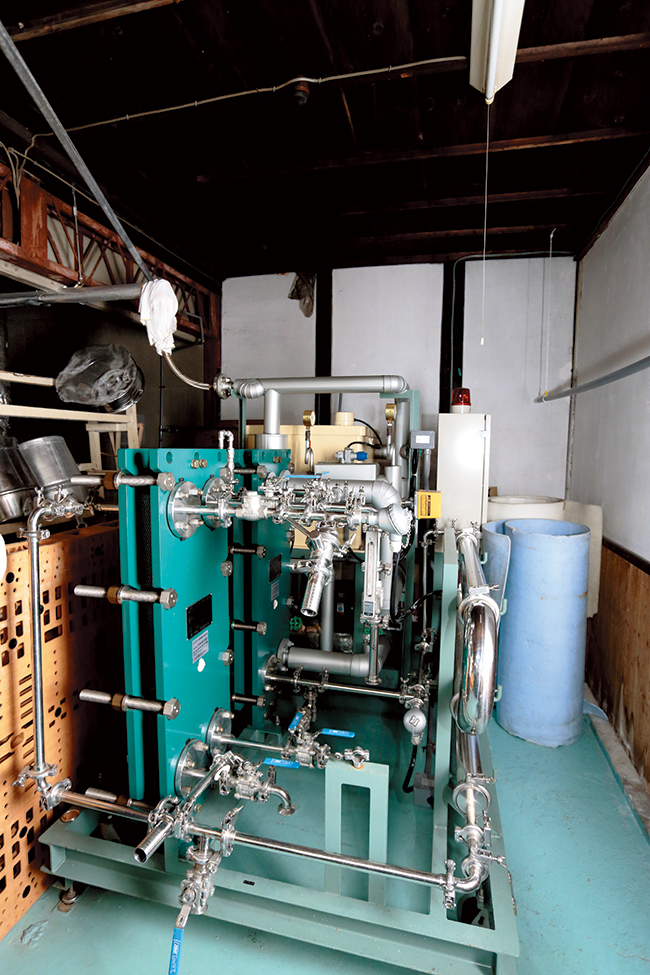

A plate type heat exchanger. Through exchange with minus 5 degrees Celsius sake, rapid cooling to 12 degrees is possible.

An original vacuum dehydrating machine.

The first stage of mashing is always prepared in a branch vat.

Pubulish at : 2014.04.20

Book : No.1 Attractive Sake World

-

Aihara Shuzo Co., Ltd

President (4th generation brewer)

Junichiro Aihara

- 1-25-15 Nigatahonmachi, Kure-shi, Hiroshima

- 0823-79-5008

- Established in 1875

- http://www.ugonotsuki.com/

Born in 1957. In March 1979, upon graduating from the Department of Fermentation Engineering, Faculty of Engineering, Hiroshima University he joined the Hiroshima Gas Group. Although he had no intention of succeeding the family business, in 1974 after the passing of third generation Tetsuya Aihara, he joined Aihara Shuzo in 1983. Appointed CEO in 1988, with meticulous implementation of "Quality First" he began a new way of sake brewing.

Interviewer・Writer Kaori Sannou

She was born and living in Osaka. After graduating from university, as a freelance writer, she covers and writes a total of more than 3,500 people through various media, including magazines, newspapers, company news letters, websites, and government publications. The goal is to describe "people" objectively and dramatically in words. She started drinking sake at the age of 20, and in 2009 became an SSI certified sake sommelier. Her hobbies are making snaks for sake, hashigo sake (bar crawl), and traveling to camps nationwide.

Photographer atsushi miyamoto

1 2